Fremont Farms of Iowa

ABOUT OUR FARMS

Our Farms

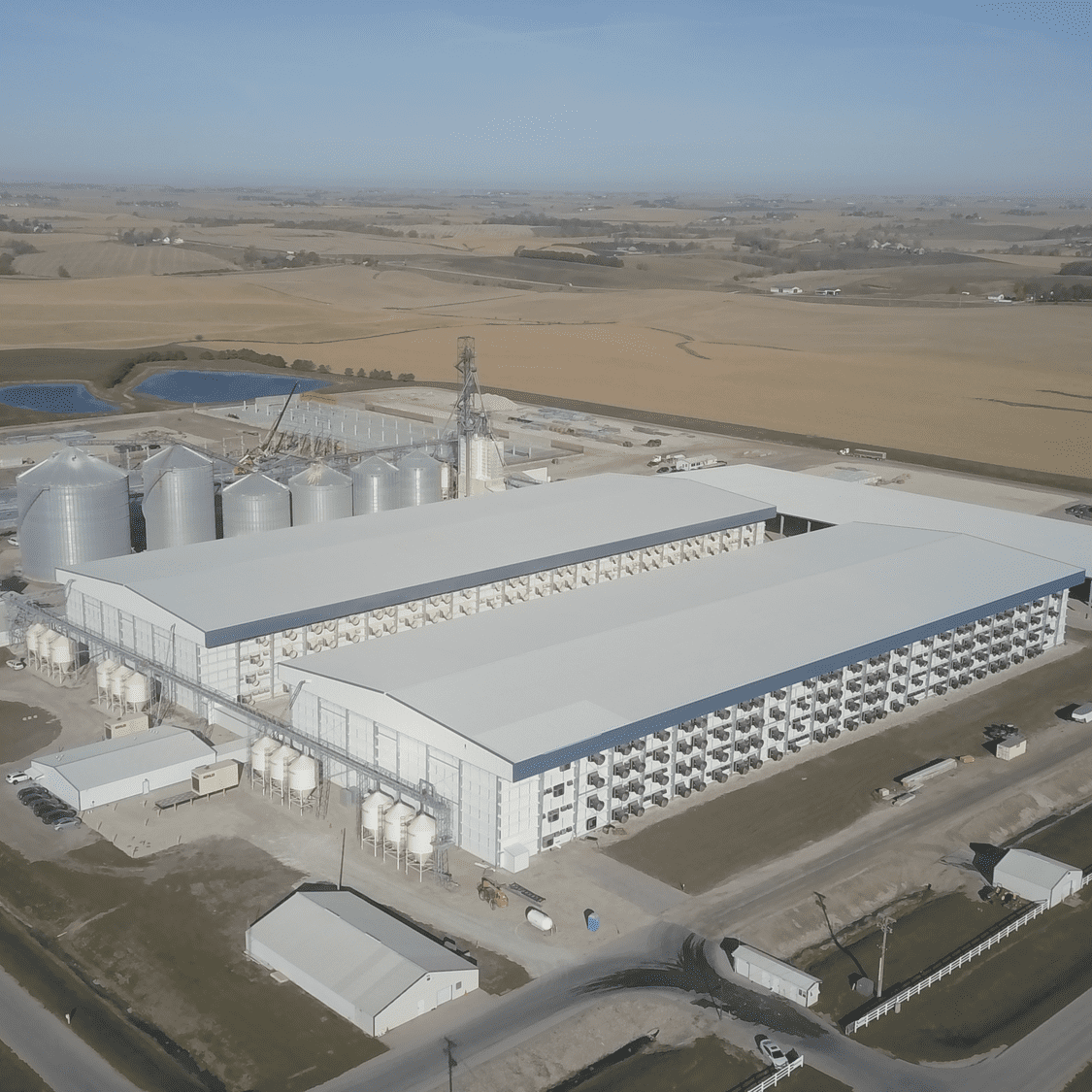

Fremont Farms of Iowa, LLP was established in 1998 by a group of family farms with long legacies in egg production. Over the years we have grown to become one of the nation’s leading producers of high-quality liquid egg products. Our family-owned egg farms include state-of-the-art cage-free and conventional pullet and layer barns, a dedicated feed mill, and an inline egg breaking facility.

In recent years, we have invested heavily in building new cage-free facilities for our pullets and laying hens. We continue to transition our operations toward cage-free liquid egg production to meet consumer demand. Our modernized farm is one of the most efficient single-site liquid egg production facilities in the country, and we make every effort to ensure that we operate sustainably.

Pullet Farm

Young hens are called pullets, and we raise ours from the time they arrive as one day old chicks. While they grow and are nurtured to move to the layer farm, we do everything possible to keep our pullets safe and healthy. Our pullet farm was developed on a separate and dedicated site for biosecurity reasons.

Our pullet farm contains infrastructure to raise both conventional and cage-free pullets. The pullets live on the pullet farm until they are ready to begin laying eggs. When the time is right, our pullets are carefully moved to the layer farm as young hens to begin their natural cycle of laying eggs.

Layer Farm

At the layer farm, our hens are housed in both cage-free and conventional layer barns. Our hens are kept safe and monitored daily while they provide us with the eggs that allow us to serve our customers.

We employ a dedicated team of feed experts at our on-site feed mill to ensure our hens are always well fed. We make our own feed by procuring millions of bushels of corn each year from valuable local farmers in addition to purchasing soybean meal, limestone, protein and other critical feed ingredients.

Liquid Egg Processing Facility

Processing Facility

Lorem Ipsum Photo Description

Lorem Ipsum Photo Description

As the name implies, our liquid egg processing facility is where eggs are sanitized, inspected, counted, broken, and prepared for sale as liquid eggs to our customers. Our sophisticated modern egg processing facility can process millions of eggs each day and safely store up to two million pounds of liquid egg.

The process starts with carefully washing and sanitizing every egg, then each egg goes through a thorough quality inspection process, and finally, only the best eggs move on to special conveyors to begin the breaking process.

The liquid egg products we produce are USDA inspected and tested for the safety and security of our customers. Every ounce of the liquid eggs we produce are cooled and securely shipped to meet the needs of our customers.

A Use for Everything

Fremont Farms is committed to caring for the land and animals that make it possible for us to make a living. Everything on our farms has a purpose, and we strive to make sure that little goes to waste.

Egg Shells

Our eggshells are dried and finely ground to add a calcium source to the pullet and layer feed we produce at our own on-site feed mill.

Egg Membranes

When eggs are separated, the protein-rich egg membrane lining the shell is extracted and used in various human health applications.

Hens

At the end of their productive life, our hens will become a protein source for the pet food industry.

Soil Conditioner

All litter is naturally dried and used to fertilize farmer crops on local area fields.

Safety First

Our business succeeds based on the health and welfare of our hens. We have made a firm commitment to managing the risk of our farms to ensure the safety and security of our operations.

Achieving Food Safety Standards

We adhere to stringent food safety protocols and follow Good Manufacturing Practices (GMP) in our egg processing facility. An on-site USDA Inspector monitors, and our lab facility conducts, continuous testing to ensure our products meet or exceed all quality standards. We also follow HACCP principles and implement systems to assure food safety from harvest to consumption.

Making Biosecurity a Priority

We strategically built our farm locations to keep our hens and pullets safe and healthy, and we consistently follow strict biosecurity policies and procedures to protect our farms from animal disease. Our new cage-free buildings were purposely constructed with shower in and shower out facilities. On a recurring basis, we conduct regular biosecurity training and participate in recurring National Poultry Improvement Plan (NPIP) audits.

Address

1600 W 19th St S

Newton, IA 50208

Phone

(641) 528-3447

info@fremontfarms.com